Crushing plants: don’t over-refine vegetable oils at the expense of lower yields

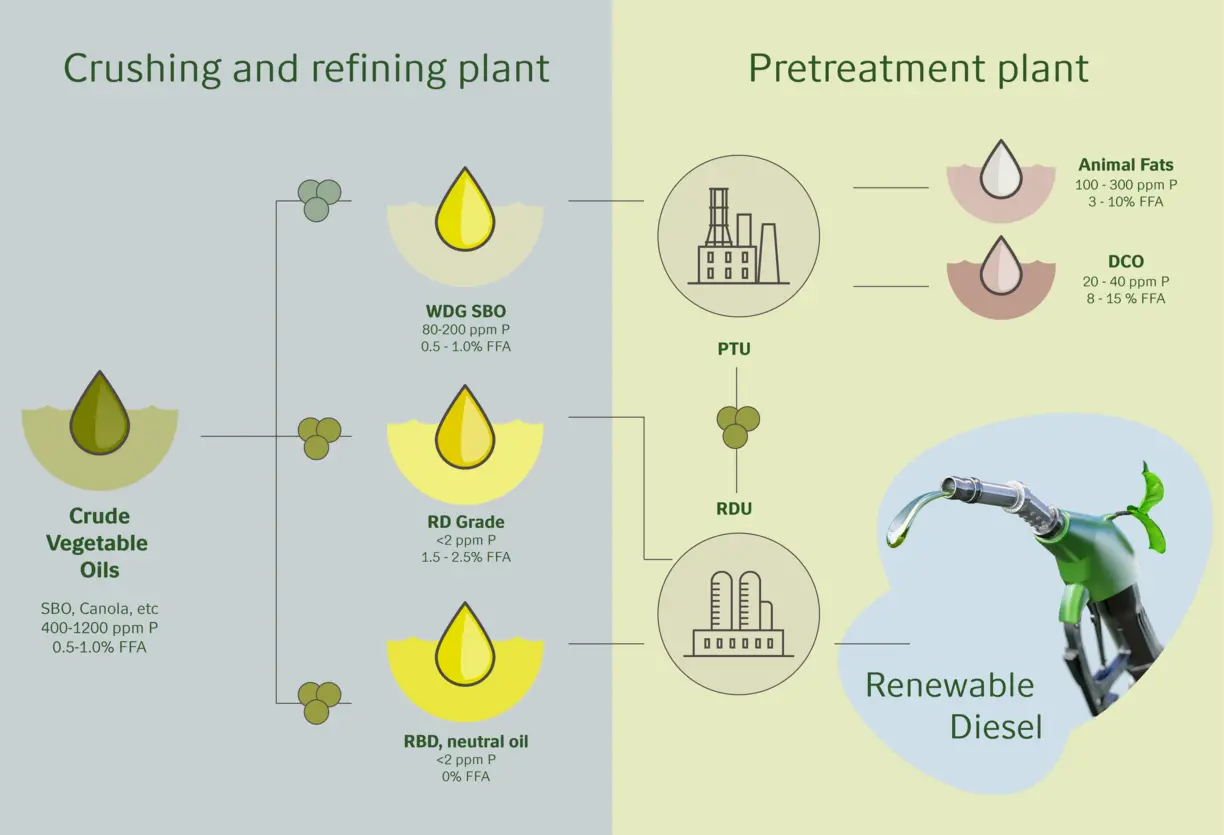

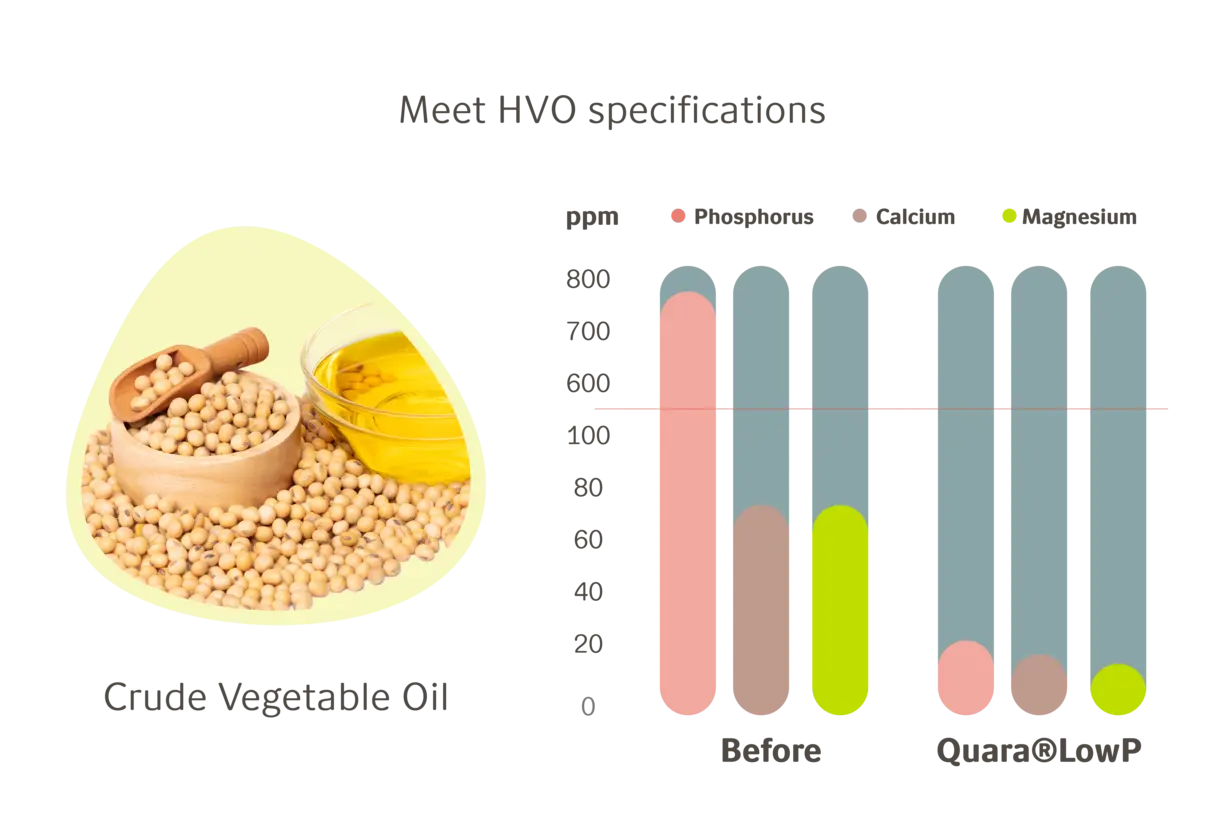

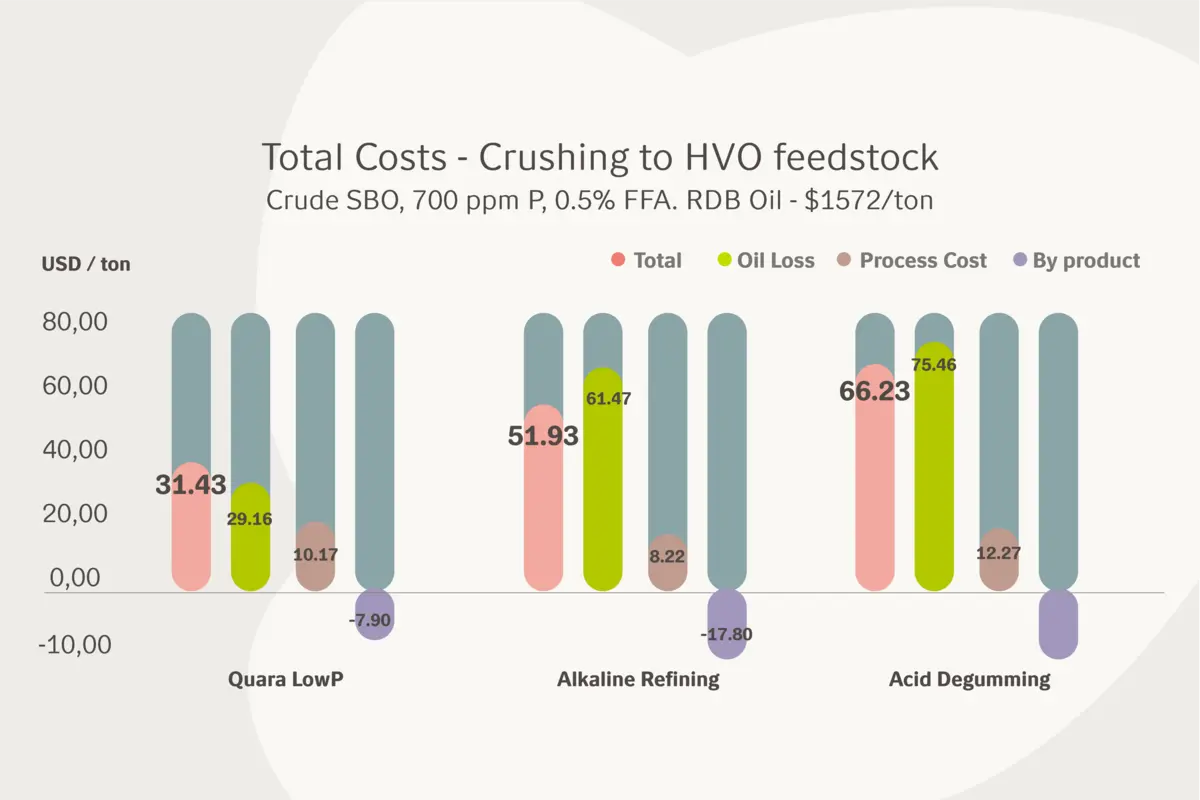

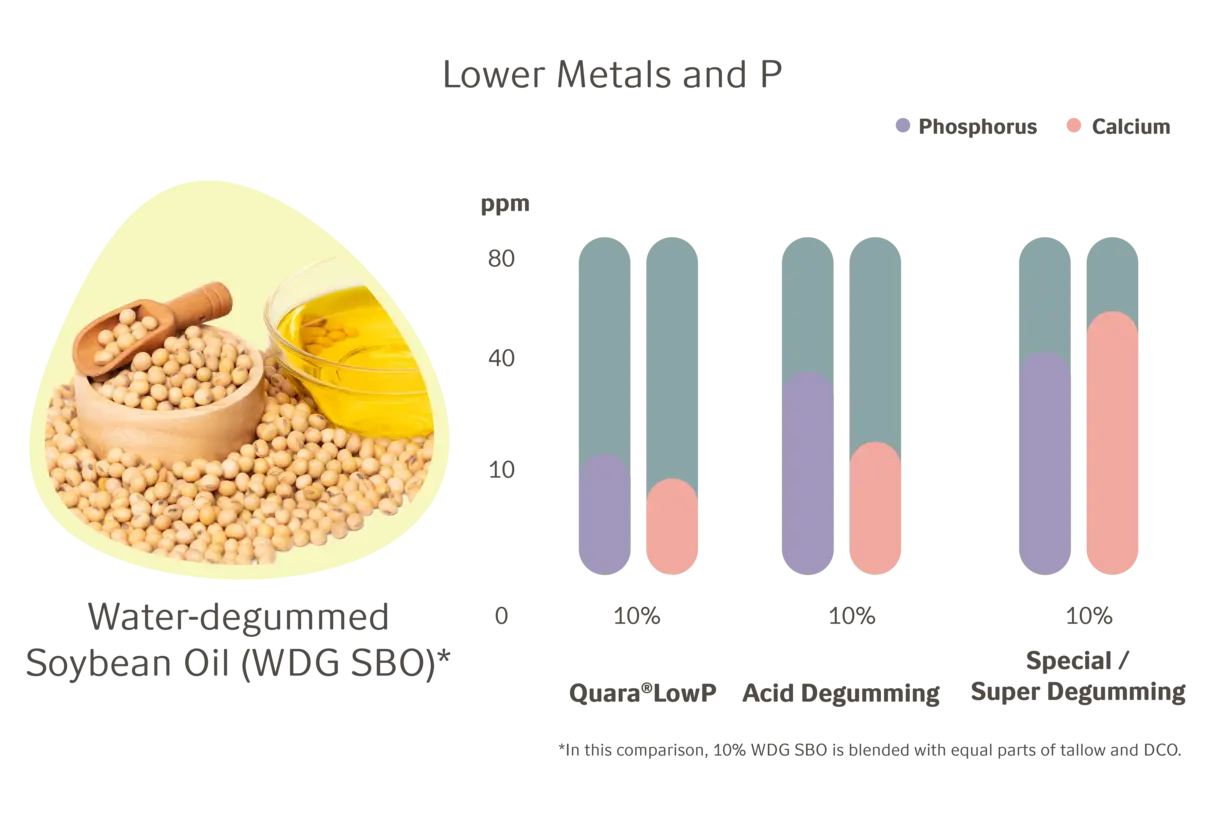

Vegetable oil refiners using chemical or physical degumming processes are unnecessarily removing valuable lipids suitable for renewable diesel production.

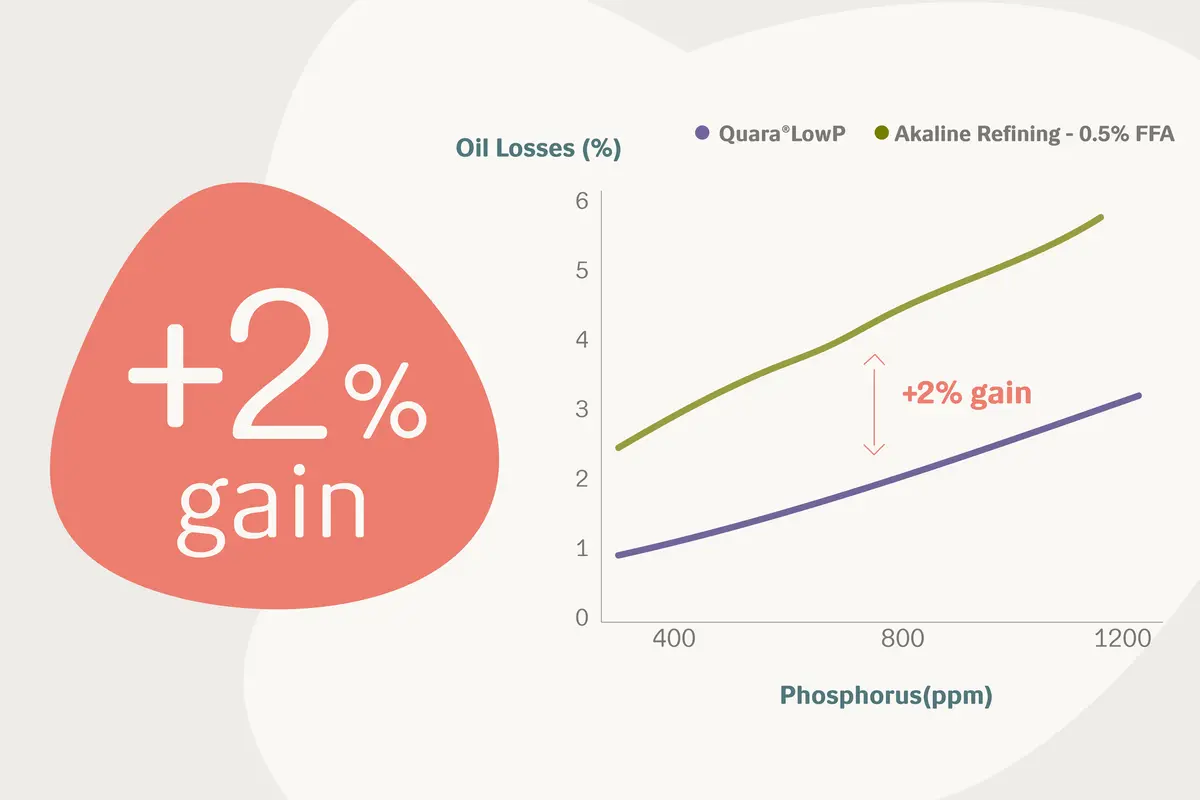

With Quara® LowP, you can avoid over-refining your vegetable oils. Target your degumming process to remove what matters—metals and phosphorous—enabling you to boost oil yield gains of up to 2%. Quara® LowP reduces your process losses, resulting in lower production of low-value by-products and improving the commercial sustainability of your operation.

Watch the video on the right to learn more.